Tube Laser Cutting Machine: How to Choose the Right Cutter

Tube Laser Cutting Machine: How to Choose the Right Cutter

Tube laser cutting machines have revolutionized the manufacturing industry, offering precision and efficiency in cutting various materials. However, selecting the right tube laser cutter can be a daunting task, especially with the myriad of options available. This guide will help you make an informed decision based on material type, cutting requirements, and budget.

Understanding Tube Laser Cutting Machines

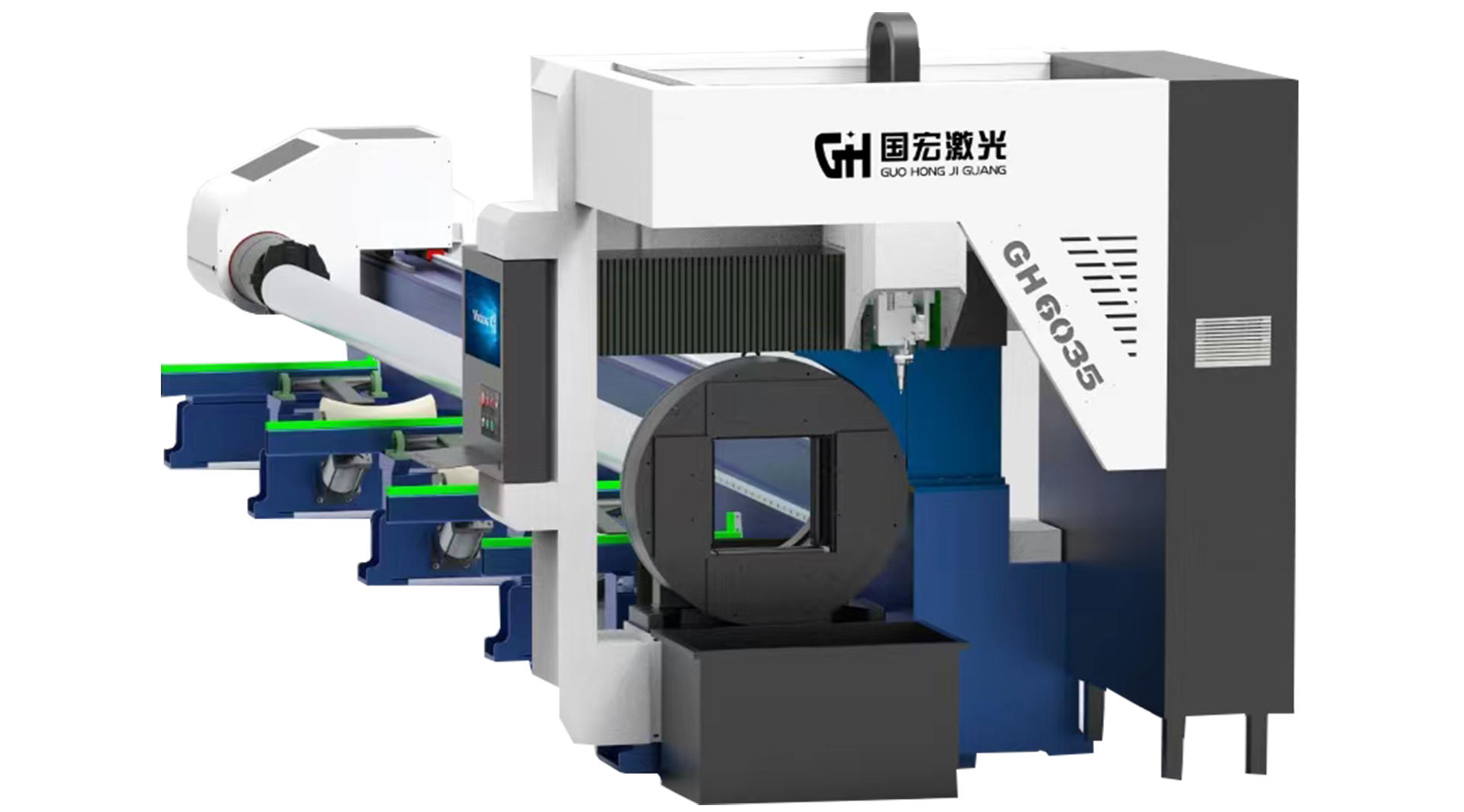

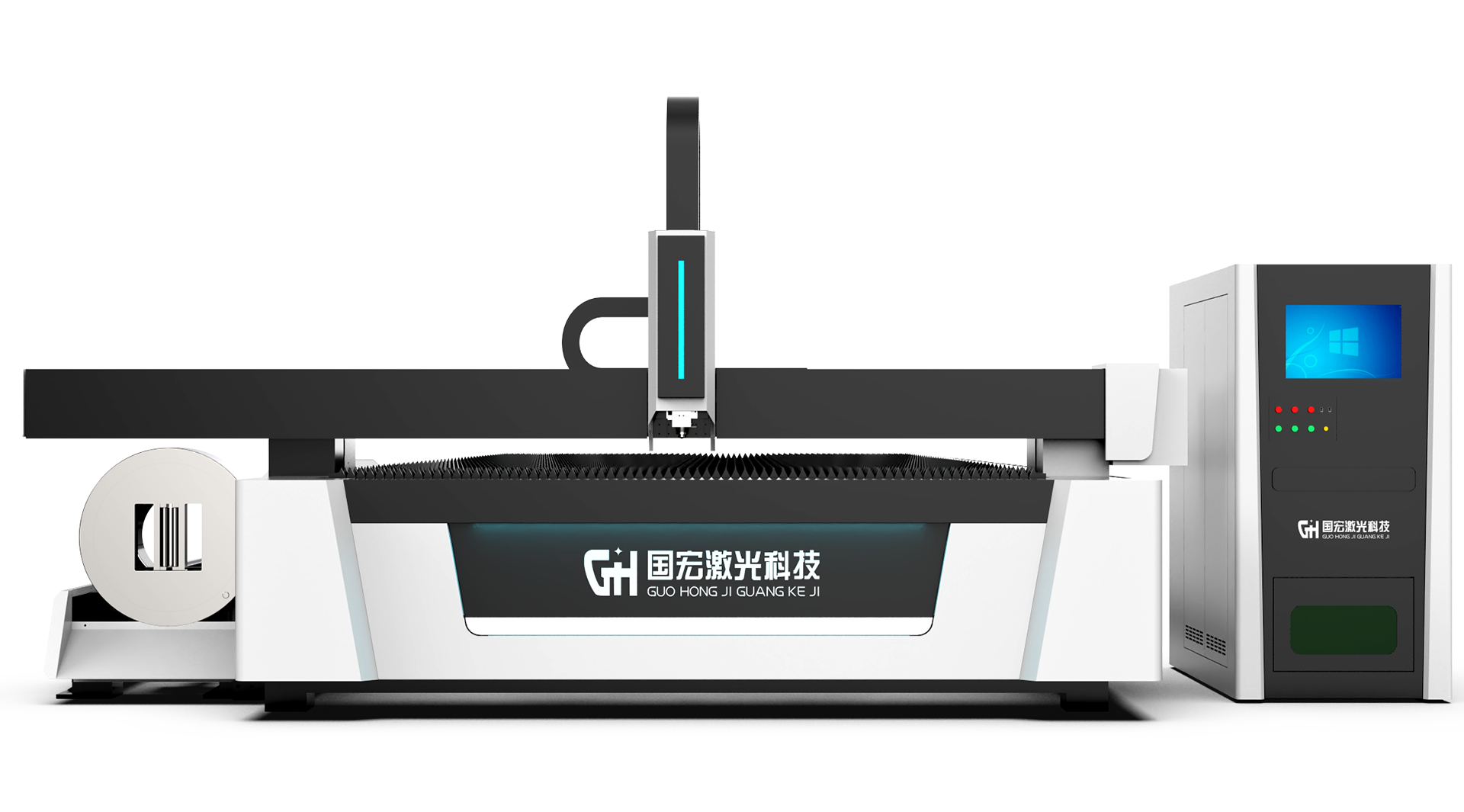

Tube laser cutting machines are specialized equipment designed to cut and shape tubes and pipes with high precision. They utilize laser technology to deliver clean, accurate cuts, making them ideal for industries such as automotive, aerospace, and construction.

Key Features to Consider

When selecting a tube laser cutter, it's essential to consider several key features:

- Material Compatibility: Ensure the machine can handle the types of materials you work with, such as steel, aluminum, or copper.

- Cutting Capacity: Consider the thickness and diameter of the tubes you need to cut.

- Precision and Accuracy: Look for machines with high precision levels to ensure clean and accurate cuts.

- Speed and Efficiency: Evaluate the cutting speed to meet your production demands.

How to Select the Right Tube Laser Cutter

Choosing the right tube laser cutter involves a thorough understanding of your specific needs. Here are some steps to guide you:

1. Assess Your Material Type

Different materials require different laser cutting capabilities. For instance, cutting stainless steel may require a higher power laser compared to cutting aluminum. Ensure the machine you choose is compatible with the materials you frequently use.

2. Determine Your Cutting Requirements

Consider the complexity and precision of the cuts you need. If your projects involve intricate designs or tight tolerances, opt for a machine with advanced features like CNC control and high-speed cutting.

3. Set a Budget

Tube laser cutting machines come in a wide range of prices. Determine your budget and look for machines that offer the best value for your investment. Remember to factor in maintenance and operational costs.

4. Evaluate Machine Specifications

Review the technical specifications of each machine, including laser power, cutting speed, and bed size. Ensure the machine meets your production requirements and can handle your workload efficiently.

5. Consider After-Sales Support

Reliable after-sales support is crucial for maintaining your machine's performance. Choose a manufacturer or supplier that offers comprehensive support, including training, maintenance, and spare parts availability.

Benefits of Investing in a Tube Laser Cutting Machine

Investing in a tube laser cutting machine offers numerous benefits, including:

- Enhanced Precision: Achieve clean, accurate cuts with minimal material waste.

- Increased Efficiency: Improve production speed and reduce downtime.

- Versatility: Handle a wide range of materials and complex designs.

- Cost-Effectiveness: Reduce labor costs and material waste, leading to long-term savings.

Conclusion

Selecting the right tube laser cutter is a critical decision that can significantly impact your production efficiency and product quality. By considering factors such as material type, cutting requirements, and budget, you can choose a machine that meets your needs and delivers optimal performance. Invest in a high-quality tube laser cutting machine to stay competitive in the manufacturing industry.

Guohong Laser Group é um fabricante de máquinas de corte a laser para metal que integra P&D, produção e vendas. Possui mais de 10 anos de experiência na produção e fabricação de equipamentos em larga escala.

Contato

+8613363699980

admin@guohonglaser.com

Lado norte da Binhu Road, lado oeste da Paoche Road, zona de desenvolvimento industrial de alta tecnologia de Pizhou